FRP Membrane Housing

CERTIFIED TO NSF/ANSI/CAN61

End port

Side Port

Double Side Port

Four Side Port

PRODUCT FINDER

ELEMENT LENGTH

NO OF ELEMENTS

Pressure

SIZE

TYPE

ALFA ≈ AEROSOL

FRP Pressure Vessels are the ideal solution for a wide range of applications including:

-

Desalination

Desalination

-

Municipal Water Treatment

Municipal Water Treatment

-

Power Generation

Power Generation

-

Food & Beverage

Food & Beverage

-

Ultrapure water production

Ultrapure water production

-

Oil & Gas

Oil & Gas

-

Refineries etc

Refineries etc

ALFA ≈ AEROSOL

FRP Membrane Housing is manufactured over procession mandrels, using a superior resin that provides the ultimate glassy finish inside it. To fabricate ALFA = AEROSOL Membrane Housing, Anu Advance Composite Products PVt Ltd has carefully selects optimal grade raw materials, which provide strength, reliability, guarantee and unparalleled performance.

Our Membrane Housing is produced with 2.5" dia up to 2 elements, 4" dia up to 6 elements and 8" dia up to 7 elements with pressure rating from 3OOPSI to 1200 PSI. Side-port is available in 4" & 8" dia Membrane Housing.

ALFA ~ AEROSOL Membrane Housing's each unit is tested in the factory at 1.5 times of its actual working pressure making it suitable to international standards of membranes. Life cycle test is also conducted on every batch of production for efficiency and longevity.

Quality Without Exception

ALFA ≈ AEROSOL is committed to producing safe, long-lasting products. We use only the highest grade materials and build our vessels to meet or exceed ASM E Section X, Class 1. & NSF/ANSI/61, NSF/ANSI/372.

Every ALFA ≈ AEROSOL vessel is subjected to rigorous quality control and hydro-testing before it leaves our factory. This means surpassing ASME cycle and burst tests, meeting stringent internal standards, and are ISO 9001 certified. This ensures that the products you receive are absolutely reliable.

2.5" End Entry Membrane Housings

| Model | Operating Pressure | Elements |

|---|---|---|

| 2540 | 300psi/ 20.7 bar | 1-2 |

| 2540 | 450psi/ 31 bar | 1-2 |

| 2540 | 600psi/ 41.4 bar | 1-2 |

4" End Entry Membrane Housings

| Model | Operating Pressure | Elements |

|---|---|---|

| 4040 | 300psi/ 20.7 bar | 1-6 |

| 4040 | 450psi/ 31 bar | 1-6 |

| 4040 | 600psi/ 41.4 bar | 1-6 |

| 4040 | lOOOpsi/ 68.9 bar | 1-6 |

4" Side Entry Membrane Housings

| Model | Operating Pressure | Elements |

|---|---|---|

| 4040SP | 300psi/ 20.7 bar | 1-6 |

| 4040SP | 450psi/ 31 bar | 1-6 |

| 4040SP | 600psi/ 41.4 bar | 1-6 |

| 4040SP | lOOOpsi/ 68.9 bar | 1-6 |

8" End Entry Membrane Housings

| Model | Operating Pressure | Elements |

|---|---|---|

| 8040 | 300psi/ 20.7 bar | 1-6 |

| 8040 | 450psi/ 31 bar | 1-6 |

| 8040 | 600psi/ 41.4 bar | 1-6 |

| 8040 | lOOOpsi/ 68.9 bar | 1-6 |

| 8040 | 1200psi/ 82.7 bar | 1-6 |

8" Side Entry Membrane Housings

| Model | Operating Pressure | Elements |

|---|---|---|

| 8040SP | 300psi/ 20.7 bar | 1-6 |

| 8040SP | 450psi/ 31 bar | 1-6 |

| 8040SP | 600psi/ 41.4 bar | 1-6 |

| 8040SP | lOOOpsi/ 68.9 bar | 1-6 |

| 8040SP | 1200psi/ 82.7 bar | 1-6 |

Note: 3 Side Port and 4 Side Port are available on the order basis.

Process

Raw Material Testing

The material is then brought to the collection chamber where a team of QC individuals check and approve the raw material for further processing of manufacture like Blow Molding, Injection Molding, Filament Winding etc.

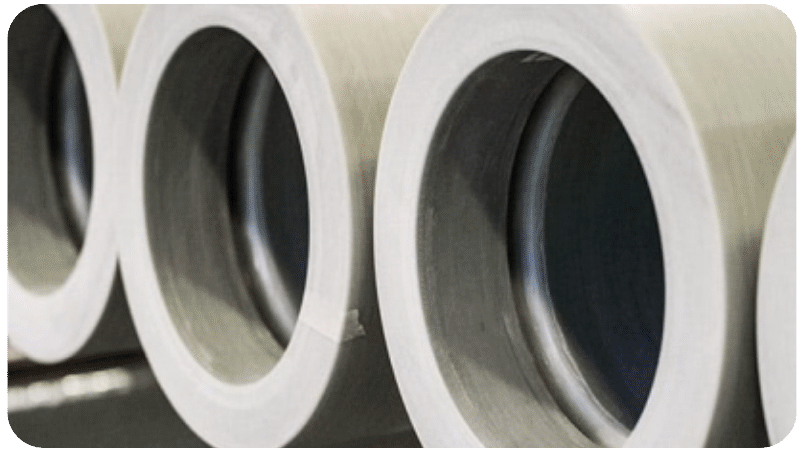

Fiberglass Filament Winding

The Membrane Housing are a combination of Fiberglass filament winding and special made glue and wound them together to the housing mould to a desired specific thickness so that the housing can bear the desired pressure.

Curing

The FRP winded housing structure is then kept into the oven for long specific hours for curing the epoxy of the membrane housing.

Grinding

The cured membrane housing is now cured and then grinding is done on the surface to get the smooth surface of the housing to get it ready for the paint.

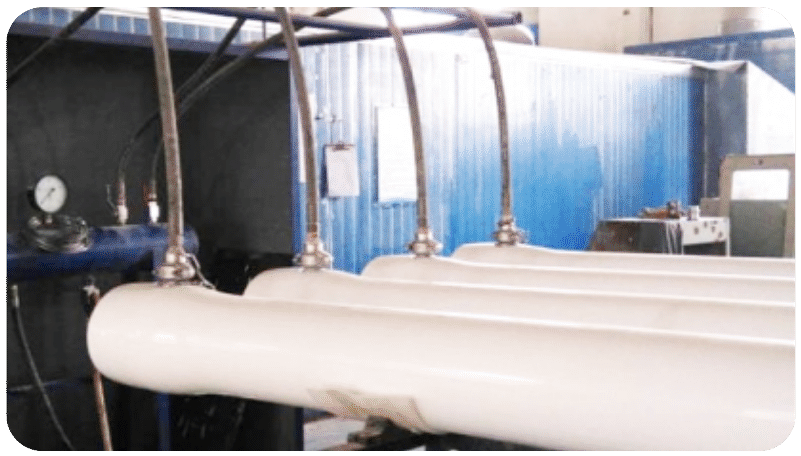

Hydro Testing

The membrane housing is now will be tested to the 1.5 times of its operating pressure for 6 minutes to confirm the housing has no leakage. We also test the membrane housing to beyond it limits at 6 times of its operating pressure which is the burst pressure of the vessel.

Painting

The special mixture paint and chemical now will be sprayed on the membrane housing to get the smooth finish on the surface of the housing.

End Cap Assembling and QC

Aer the assembling of the end cap into the housing our special team of qualified engineers of QC department test the membrane housing with every specific details required to test before the dispatch. Once approved, the membrane housing will the transferred to the packing section.

Labelling, Packing & Dispatch

The membrane housing will now be labeled and packed with specially made corrugated boxes to prevent any damage in transportation. A complete furnished Membrane Housing with extreme fine quality will now be ready to be dispatch to our respected clients.

Trusted Partners